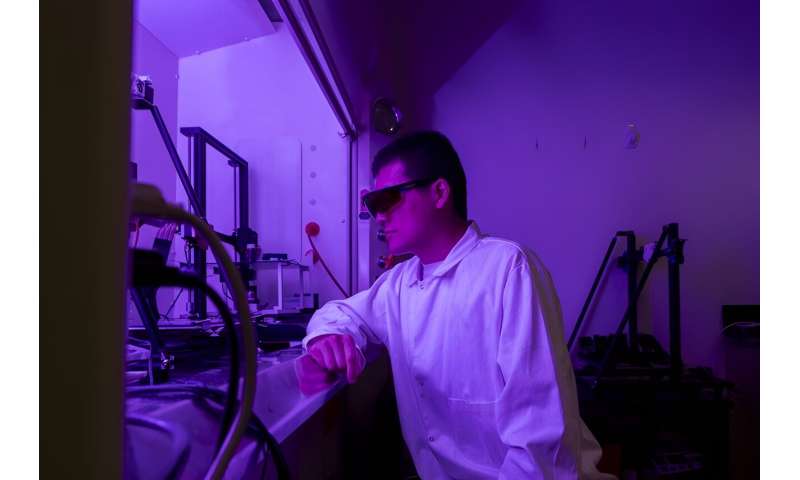

Researchers at the University of Missouri have built a machine that combines elements of traditional 3D printing with laser technology to develop multi-material, multi-functional products. Credit: Sam O’Keefe

Researchers at the University of Missouri have developed a way to create complex devices with multiple materials — including plastics, metals and semiconductors — all using a single machine.

Research recently published in The nature of communicationoutlines a new 3D printing and laser process for manufacturing multi-material, multi-layer sensors, circuit boards and even textiles with electronic components.

It’s called the Freeform Multi-material Assembly Process, and it promises to revolutionize the production of new products.

By printing sensors built into the structure, the machine can create things that can sense environmental conditions, including temperature and pressure. For other researchers, it could mean having a natural-looking object like a rock or seashell that could measure the movement of ocean water. For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

“This is the first time this type of process has been used, and it opens up new possibilities,” said Bujingda Zheng, a doctoral student in mechanical engineering at Mizzou and lead author of the study. “I’m passionate about design. I’ve always wanted to do something that no one has done before, and I get to do that here at Mizzou.”

One of the main advantages is that innovators can focus on designing new products without having to worry about how to prototype them.

“This opens up the possibility for entirely new markets,” said Jian “Javen” Lin, associate professor of mechanical and aerospace engineering at Mizzou. “It will have a broad impact on wearable sensors, customizable robots, medical devices and more.”

Revolutionary techniques

Currently, manufacturing a multilayer structure – such as a printed circuit board – can be a cumbersome process involving multiple steps and materials. These processes are expensive, time-consuming and can create waste that harms the environment.

Not only is the new technology better for the planet, it’s inspired by systems found in nature.

“Everything in nature consists of structural and functional materials,” Zheng said. “For example, electric eels have bones and muscles that allow them to move. They also have specialized cells that can discharge up to 500 volts to deter predators. These biological observations have inspired researchers to develop new methods for producing 3D structures with multifunctional applications, but other new emerging methods have limitations.”

-

PhD student Bujingda Zheng uses 3D printing and a laser process to produce multi-material, multi-layer sensors, printed circuit boards and textiles with electronic components. Credit: Sam O’Keefe

-

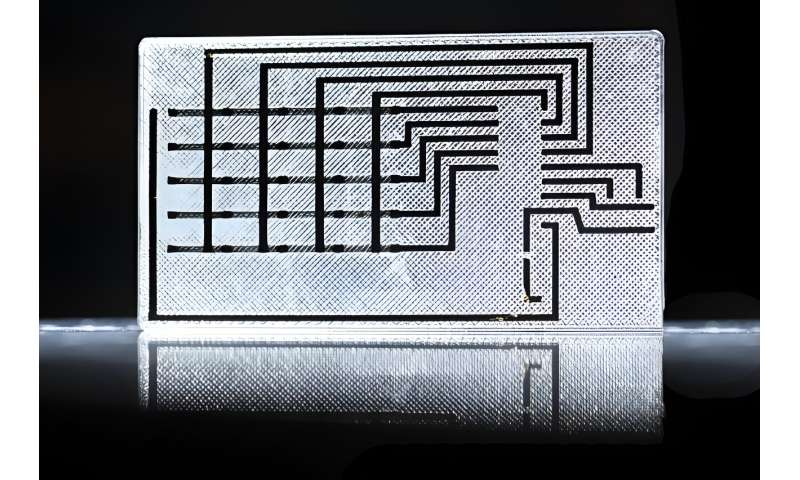

An example of electrodes printed inside a plastic material. Credit: Sam O’Keefe

In particular, other techniques lag behind in terms of how versatile the material can be and how precisely smaller components can be placed into larger 3D structures.

The Mizzou team’s method uses special techniques to solve these problems. Team members built a machine that has three different nozzles: one adds an ink-like material, another uses a laser to carve out shapes and materials, and a third adds other functional materials to enhance the product’s capabilities. It begins by creating a basic structure with common 3D printing filament such as polycarbonate, a type of transparent thermoplastic. It then switches to a laser to turn some parts into a special material called laser-induced graphene, which places it exactly where it’s needed. Finally, other materials are added to increase the functional capabilities of the final product.

“The I-Corps program helps us identify market interests and needs,” Lin said. “Currently, we believe this could be of interest to other researchers, but we believe it will ultimately benefit businesses. It will reduce production time for device prototyping by allowing businesses to produce prototypes in-house. This technology, available only at Mizzou, shows great promise for transforming the way products are made and manufactured.”

More information:

Bujingda Zheng et al, Programmed multi-material assembly by synergistic 3D printing and free laser induction, The nature of communication (2024). DOI: 10.1038/s41467-024-48919-5

Provided by the University of Missouri

Citation: No Assembly Required: Innovative 3D Printing Method Streamlines Multi-Materials Manufacturing (2024, June 24) Retrieved June 25, 2024, from https://techxplore.com/news/2024-06-required-3d-method-multi-materials .html

This document is subject to copyright. Except for any bona fide act for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.