The production of pencils in New Jersey and the production of massive wind turbines in North Dakota are included in this summary of American industrial facilities photographed by Christopher Payne.

Payne has spent the past decade researching factories in America, from “traditional industries” such as wool carders to the production of contemporary technological machinery, which he says is often “hidden from plain sight.”

His reasons for creating Made in America stem from a lack of awareness of where products come from and American manufacturing “coming back” post-Covid-19.

“Most people I know have never set foot in a factory,” Payne said. “Decades of global outsourcing and a flood of cheap imports have decimated the American manufacturing sector and emptied once-thriving communities.”

“Yet we still live in the physical world and surround ourselves with material things, and many of these things are still made in America. As environmental concerns and pandemics become urgent wake-up calls, we need to rethink global supply chains.” , American manufacturing is coming back.”

The book features detailed photographs taken from Payne’s personal research and editing assignments and has an introduction by British author Simon Winchester.

Payne said he wanted to preserve the heritage of certain industries while showing the continued innovation and skills of the workers — many of whom are in the photo.

“All of these places share a commitment to craftsmanship and quality that cannot be outsourced,” he said.

“There’s certainly a certain romance to the idea of making your own goods here in the US, but it’s not all nostalgia anymore, it’s also a necessity and an opportunity.”

Read Payne’s commentary on scenes from twelve industrial facilities in the United States:

S & D Spinning Mill, Millbury, Mass

“In 2010, I discovered an old yarn mill in Maine that reminded me of the state hospital workshops I photographed for my book Asylum. While most such places were long abandoned, this mill was fully functional, a scene from the past miraculously coexisting with the present. “

“I learned about other mills in New England, remnants of a once-dominant industry that had long ago moved south and then overseas in search of cheap labor. I befriended mill owners who, in addition to opening their doors, informed me of the varied production, an invaluable tip that transformed a drab, monochromatic scene into something photogenic and magical.”

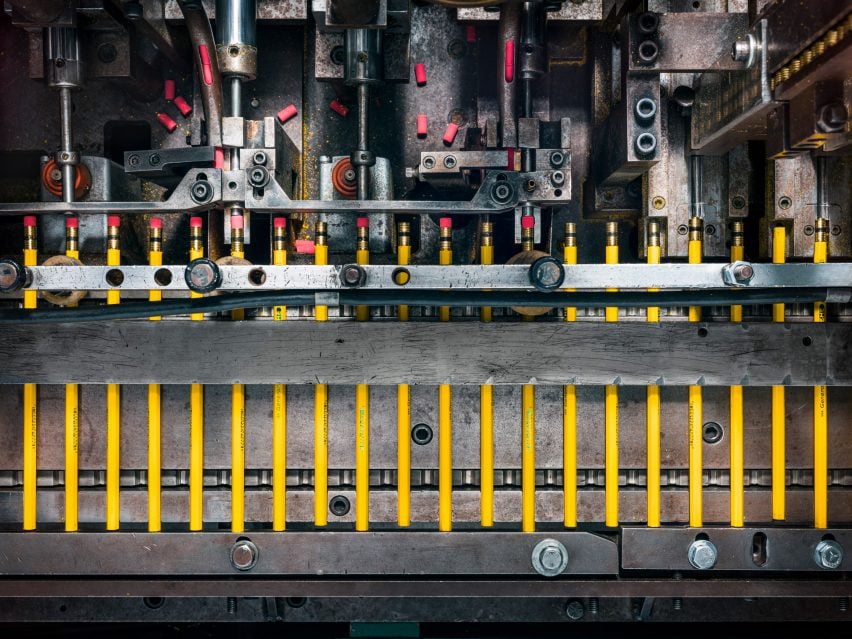

General Pencil Company, Jersey City, New Jersey

“General Pencil is one of two remaining pencil companies in the US and it took five years to gain the trust of the owners and access to the factory.”

“I focused on the basic steps in the manufacturing process to reveal a new perspective on this humble, everyday object.”

Global Foundries, Malta, New York

“Traditionally manufactured objects such as pianos and pencils are well known, which makes them easier to photograph than small microchips. [featured above] or a complex, one-of-a-kind spacecraft; they are recognizable at all stages of production and we know exactly what they are doing.”

“Whenever possible, I try to include people in my images to humanize a subject that might otherwise seem incomprehensible.”

GE Aerospace, Lafayette, Indiana

“It’s impossible to appreciate the size and complexity of a jet engine from an airplane window.”

“Viewed up close and exposed, it becomes a complex, dazzling work of art, a perfect balance of form and function.”

GE Gas Power, Schenectady, New York

“Getting access to modern factories is never easy. There are security and intellectual property concerns that didn’t exist in the 1940s and 1950s, when American companies spent lavishly on annual reports and were eager to pull back the curtain on popular magazines like LIFE.” and Fortune.”

“Sometimes I’ll take a beautiful shot only to find later that I can’t use it, prompting me to look elsewhere for a replacement like this, which was my second – and successful – attempt at photographing a turbine rotor.”

Corning Inc, Canton, New York

“Glass is an ancient material that keeps pushing itself to new limits, but it’s not easy to photograph. It’s transparent, reflective, and often quite thin and fragile.”

“Finding this technician hovering over a huge glass circle, lit up like an ice sculpture, was something I’d never seen before, and it remains one of my favorite images.”

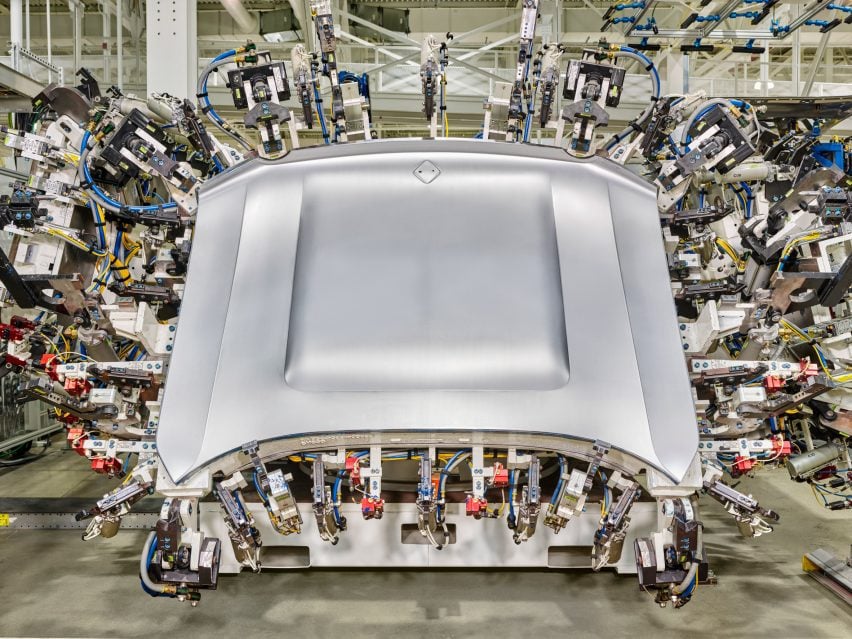

Rivian, Normal, Illinois

“The car factories are so vast that you need a golf cart to travel around them. The environments are visually stunning and everything beckons for the camera.”

“I never have enough time to show even a fraction of the production process, so I look for quiet, simple moments that serve as stand-ins for a larger story.”

Build Your Dreams Factory (BYD), Lancaster, California

“I approach industrial subjects and busy, crowded factories in the same way as buildings: I try to find an underlying order in the visual chaos.”

“Here I was able to use the frame of the bus as a geometric backdrop on which the action could unfold, like a stage.”

Interface, LaGrange, Georgia

“New technologies are often seamlessly integrated into everyday products in ways that are unrecognizable, as in this case where captured carbon dioxide is sealed into the backing of a commercial carpet.”

“Even if the product is ‘high tech’, the manufacturing process still requires the deft touch of the human hand.”

LM Wind Power, Grand Forks, North Dakota

“Clean energy is another booming industry in manufacturing. Wind turbine blades are 60 to 91 meters long, so there’s no elegant way to show their length without including a lot of distractions.”

“In section, however, the semicircle of the blade sheath becomes a pleasing composition that fills the frame.”

Space Relativity, Long Beach, California

“Core technologies like aerospace have been reinvigorated by the private sector and new technologies like 3D printing, and some of the factories I visited had a buzz of tech startups.”

“Relativity Space 3D prints rocket engines, reducing the time it takes to do this from years to months. To get around the UV light from the laser, we had to wear protective gear to avoid getting a nasty burn.”

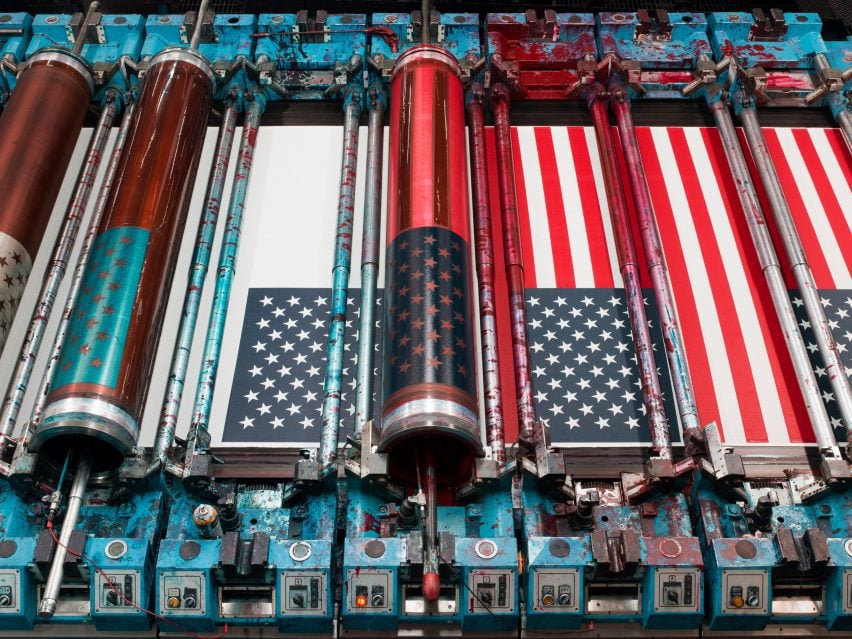

Annin Flagmakers, South Boston, Virginia

“Even in its unfinished state, the American flag is instantly recognizable, the whole greater than the sum of its parts.”

“I like to think of a factory as similar, a whole that is only complete when everyone is working together as a team. It is the people who make the things that drive our economy, and in this age of social polarization and increasing automation offer a glimmer of hope .”