Scientists from ETH Zurich have successfully demonstrated the levitation of a silicon dioxide nanoparticle in a high vacuum on a hybrid photonic-electric chip. This significant achievement, detailed in their latest study published in Nature Nanotechnologyrepresents a major leap forward in the field of nanotechnology and opens up new possibilities for future technological applications.

Breakthrough is the latest in the series advances in nanotechnologywhich has led some leading futurists to predict that developments in biotechnology, artificial intelligence and nanobots will significantly affect the future of humanity in the coming years.

“Vacuum levitation has evolved into a versatile technique… [and] holds great promise for advancing the study of quantum mechanics in the unexplored macroscopic regime,” the study authors wrote. “However, most current levitation platforms are complex and bulky.

“Here we show levitation and motion control in high vacuum of a silicon dioxide nanoparticle on the surface of a hybrid optical-electrostatic chip.”

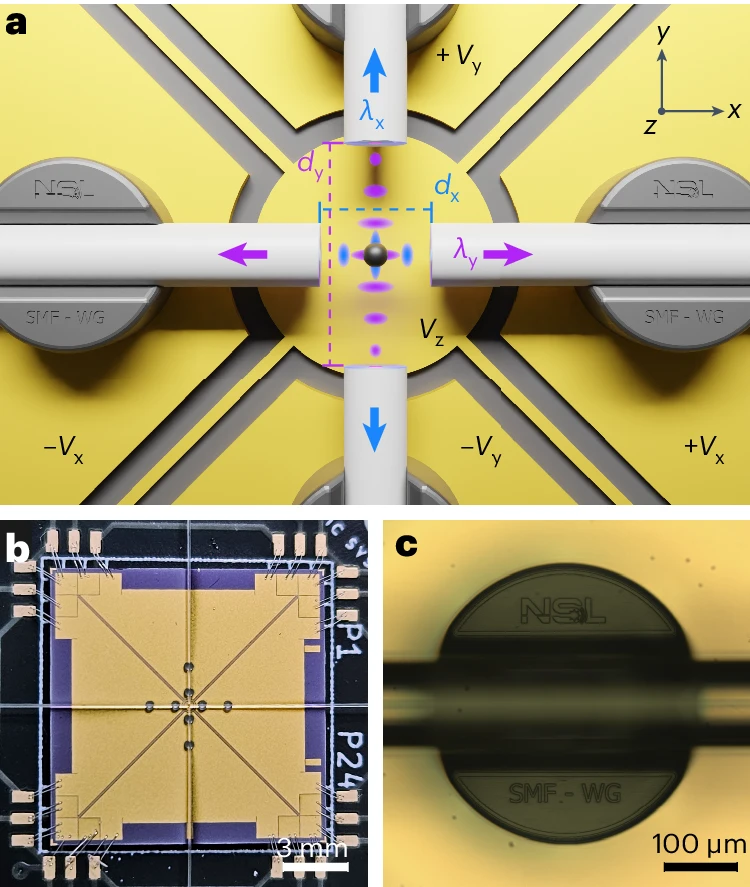

The ETH Zurich team’s hybrid chip consists of two layers: an upper photonic layer where the nanoparticle is captured and detected, and a lower electrical layer with planar electrodes for feedback cooling.

This setup enables accurate detection of nanoparticle motion by analyzing scattered light. This method achieves high signal-to-noise ratios without the need for bulky high numerical aperture lenses.

Practically speaking, the photonic layer contains four orthogonal split single-mode optical fibers. These fibers form standing waves that create multiple trapping sites, effectively canceling dispersive forces and providing robust particle retention. The bottom layer uses electrodes for feedback cooling, stabilizing the movement of the particle in three dimensions and enabling precise control.

This hybrid photonic-electric platform enables robust levitation, precise position detection and dynamic control of nanoparticles in vacuum without bulky optical equipment.

This compact design could make the technology more practical for real-world applications, including portable devices and confined spaces such as cryostats.

The primary advantage of this new method of vacuum levitation lies in the integration of optical and electrostatic components on a single chip, which enables high precision and control over the movement of nanoparticles.

While this breakthrough primarily focuses on microscopic particles, the word “levitation” raises interesting questions about its implications for larger levitation technologies, including advanced propulsion systems.

Microscopic vacuum levitation, such as the levitation of silica nanoparticles demonstrated in this recent study, is fundamentally different from the larger-scale levitation that people may associate with science fiction concepts such as flying cars or “anti-gravity.”“ by ship.

At the microscopic level, levitation is achieved through precise control of electromagnetic fields and laser cooling techniques in highly controlled environments, typically a vacuum. These methods focus on counteracting the forces acting on tiny particles, allowing them to float or be suspended without physical contact.

In contrast, levitation on a larger scale, such as is envisioned for exotic flying vehicles or spacecraft, would require overcoming the gravitational force acting on much larger masses.

This would likely involve entirely different principles, such as magnetic levitation (maglev), which uses powerful magnets to lift and propel vehicles, or potential future technologies that are currently theoretical.

The technical and energy requirements for such large-scale levitation are exponentially more significant, and the environmental conditions are more varied and difficult to control compared to a vacuum-sealed laboratory.

Finally, microscopic levitation is a well-studied and practical technique with existing technological applications. Large-scale levitation, such as flying cars or “anti-gravity”.“ technology, remains theoretical.

Instead of trying to achieve levitation, most experts working on next-generation propulsion systems focus on concepts such as functional warp drives and hybrid plasma propulsion systems.

This means that the ability to levitate and control nanoparticles in high-vacuum conditions could revolutionize several fields, including quantum computing, materials science and precision sensing.

The work of ETH Zurich researchers offers a glimpse into a future where miniaturized integrated levitation systems enable new experimental protocols and applications.

One of the most promising applications is in quantum mechanics. Precise control of nanoparticle motion can facilitate complex state preparation and readout, which is essential for quantum computing.

Integrating photonics and nanophotonics with artificial electric potentials improves control over particle motion and paves the way for scalable quantum systems.

Additionally, the ETH Zurich team’s approach could influence advances in sensing technologies. By achieving high vacuum levitation, researchers can create more sensitive force and torque sensors, which are crucial for scientific experiments requiring precise measurements at microscopic scales.

Despite the promising results, several issues still need to be resolved. The stability and robustness of the levitation system in different environments, the scalability of the technology, and the integration with other quantum systems are areas for future investigation.

The ETH Zurich team is already planning further improvements to its platform. Future studies will focus on increasing the detection sensitivity using refractive microlenses and integrating more sophisticated optical elements such as fiber cavities. The goal of these improvements is to achieve even greater control over particle motion and pave the way for comprehensive state preparation and reading.

ETH Zurich’s breakthrough in high-vacuum levitation of silicon dioxide nanoparticles on a chip marks a major milestone in nanotechnology. Its potential applications in quantum computing, sensing technologies and materials science underscore the importance of continued research and development in this area. As technology evolves, it promises to open up new horizons for scientific research and practical innovation.

“We envision our platform as an initial springboard to exploit hybrid potentials for quantum experiments based on levitating particles,“ the researchers concluded.

Tim McMillan is a former law enforcement executive, investigative reporter and co-founder of The Debrief. His writing typically focuses on defense, national security, the intelligence community, and psychology-related topics. You can follow Tim on Twitter: @LtTimMcMillan. Tim can be contacted by email: tim@thedebrief.org or via encrypted email: LtTimMcMillan@protonmail.com