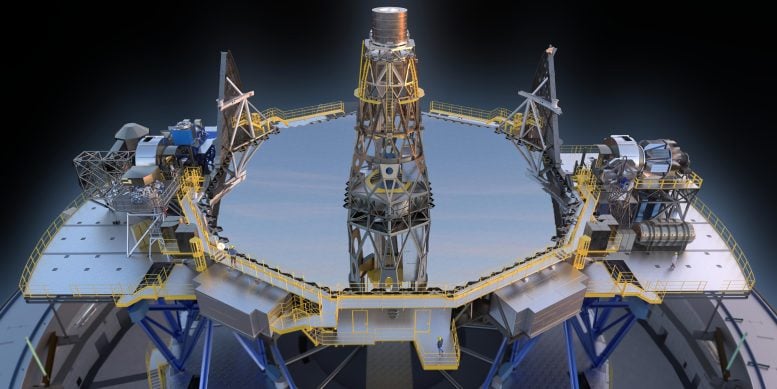

This artist’s rendering shows a nighttime view of the Extremely Large Telescope in operation on Cerro Armazones in northern Chile. The telescope is shown using lasers to create artificial stars high in the atmosphere. Credit: ESO/L. Calçada

The last part of the mirror of the largest telescope in the world has been successfully cast

The Extremely Large Telescope in Chile, which will be completed this decade, will be the largest telescope in the world, with a main mirror spanning 39 meters and made of 798 precision-machined segments. It represents a major international effort in astronomy.

The European Southern Observatory’s Extremely Large Telescope is currently being built in Chile’s Atacama Desert (ACEELT) is one step closer to completion. The German company SCHOTT has successfully delivered a blank for the last of the 949 segments commissioned for the telescope’s primary mirror (M1). At more than 39 meters in diameter, M1 will be by far the largest mirror ever made for a telescope.

Innovation in telescope mirror design

M1, which is too large to be made from a single piece of glass, will consist of 798 hexagonal segments, each about five centimeters thick and 1.5 meters in diameter, which together will collect tens of millions of times more light than the human eye. An additional 133 segments were produced to facilitate maintenance and overlap the segments once the telescope is in operation. ESO also acquired 18 replacement segments, bringing the total to 949.

The primary mirror of ESO’s Extremely Large Telescope (ELT), known as M1, will be by far the largest mirror ever made for a telescope. At more than 39 meters in diameter, M1 is too large to be made from a single piece of glass and will instead consist of 798 hexagonal segments, each about five centimeters thick and 1.5 meters in diameter, which together collect dozens million times. as much light as the human eye. An additional 133 segments were produced to facilitate maintenance and overlap the segments once the telescope is in operation. ESO also procured 18 spare segments, bringing the total to 949. The German company SCHOTT has now successfully cast the blank for the last of the 949 segments, seen in this photo. The M1 blanks, shaped pieces of material that are later polished to become mirror segments, are made of ZERODUR©, a low-expansion glass-ceramic material developed by SCHOTT and optimized for the extreme temperature ranges of the ELT site in the Atacama desert. . This image shows the 949th segment before it is cut into its hexagonal shape and polished, steps carried out by the French company Safran Reosc. Credit: SCHOTT

Advanced materials and manufacturing techniques

The M1 blanks, shaped pieces of material that are later polished to become mirror segments, are made of ZERODUR®, a low-expansion glass-ceramic material developed by SCHOTT and optimized for the extreme temperature ranges at the ELT site in the Atacama Desert. . This company also produced blanks for three other ELT mirrors – the M2, M3 and M4 – at its facilities in Mainz, Germany.

Collaboration and precision engineering

“What ESO ordered from SCHOTT is more than just ZERODUR®,” says Marc Cayrel, Head of ELT Optomechanics at ESO. “Working closely with ESO, SCHOTT fine-tuned every single manufacturing step and customized the product to meet and often exceed the very demanding requirements of the ELT. The excellent quality of the blanks was maintained throughout the serial production of more than 230 tons of this super-performance material. ESO is therefore very grateful for the professionalism of the qualified teams at SCHOTT, our trusted partner.”

Computer rendering showing the main mirror (M1) of the ESO Extremely Large Telescope. Credit: ESO

Thomas Werner, ELT project manager at SCHOTT, says: “Our entire team is excited about the largest single order for ZERODUR® in our company’s history. For this project, we have successfully completed the serial production of hundreds of ZERODUR® mirror substrates, when we usually have a piece run. It has been an honor for all of us to play a role in shaping the future of astronomy.”

International logistics and assembly

Once cast (see video below), all segments follow an international journey in several steps. After a sequence of slow cooling and heat treatment, the surface of each blank is shaped by ultra-precision grinding at SCHOTT. The blanks are then transported to the French company Safran Reosc, where each one is cut into a hexagon shape and polished to a precision of 10 nanometers across the entire optical surface – meaning the mirror’s surface roughness will be less than one thousandth. the width of a human hair.

Further participating in the work on the M1 segment assemblies are: the Dutch company VDL ETG Projects BV, which manufactures the segment supports; the German-French consortium FAMES, which has developed and is completing production for 4500 nanometersaccuracy sensors monitoring the relative position of each segment; German company Physik Instrumente, which designed and manufactures 2,500 actuators capable of positioning a segment with nanometric precision; and the Danish company DSV, which is in charge of transporting the segments to Chile.

After being polished and assembled, each M1 segment is transported across the ocean to reach the ELT technical facility at ESO’s Paranal Observatory in the Atacama Desert – a 10,000 kilometer journey that has already been completed by over 70 M1 segments. In Paranal, just a few kilometers from the ELT construction site, each segment is coated with a silver layer to make it reflective and will then be carefully stored until the telescope’s main structure is ready to receive them.

Final phase and future impact

When it becomes operational later this decade, the ELT ELT will be the largest eye in the sky in the world. It will tackle the greatest astronomical challenges of our time and make unimaginable discoveries.