The European Space Agency has created its own version of a Lego brick that is 3D printed from meteorite dust as the organization explores how to build buildings in space.

The “Space Bricks,” as Lego and the European Space Agency (ESA) call them, are made from the dust of a 4.5-billion-year-old meteorite discovered in 2000 in northwestern Africa.

Meteorite dust acts as a stand-in for lunar regolith—the loose material covering the surface of Earth’s moon that is largely the product of meteorite impacts.

Because there is only a small amount of regolith on Earth—the samples brought back during the Apollo missions—scientists settled on the closest substitute they could find.

The development of space bricks is part of ESA’s contribution to the international Artemis program, which aims not only to return astronauts to the Moon, but also to establish a lunar base there.

Since bringing materials from Earth is considered too expensive and time-consuming, the hope is that lunar regolith can be used to build structures such as launch pads and habitats.

In space exploration, this is known as in-situ resource utilization (ISRU) and is the focus of ESA’s EAC spacecraft team based in Cologne, Germany.

ESA Science Officer Aidan Cowley, who heads the lab, said his team loved “creative construction” and had the idea to explore whether space dust could be formed into a small Lego-like block to test different construction techniques.

“Our teams are working on the future of space travel, taking inspiration not only from what’s above us, but also from what we can find on Earth,” Cowley said.

“No one has ever built a structure on the moon, so we have to figure out not only how we build them, but also what we build them out of, because we can’t take any material with us.”

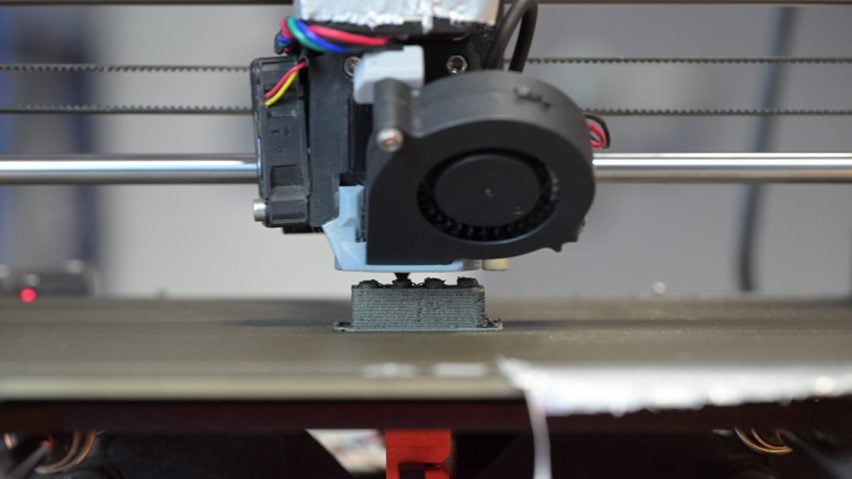

To get the material suitable for 3D printing, the team ground pieces of the meteorite into powder and mixed it with a small amount of polylactic acid – a type of biodegradable bioplastic – as well as a “regolith simulator”, a mixture of Earth minerals. they resemble the composition of the lunar surface.

Their design is close to the shape and size of Lego bricks, although accuracy is difficult to recreate at this scale with 3D printing and required a lot of fine-tuning, according to ESA.

The team said that because of this, Lego brick shapes have become “a common test for this kind of project”.

The blocks also work on the same principle as Lego, with tubes on the bottom of the blocks fitting into pins on the top of the blocks below. This connection system creates the “clutch force” that makes Lego bricks so great to take apart.

“The result is amazing, and although the dice may look a little rougher than usual, the important thing is that the clutch performance still works, allowing us to play and test our designs,” said Cowley. “It was both fun and helpful in scientifically understanding the limits of these techniques.”

The Lego Group has now put 15 ESA space bricks on display in its stores around the world as the company hopes to inspire children to build their own space shelters.

The Artemis program has been running since 2017 and a manned lunar landing is scheduled for late 2026. The program also saw construction company ICON working on 3D printing technology for the moon, fashion house Prada creating spacesuits, and Lockheed Martin, General Motors and Goodyear developing a lunar vehicle .